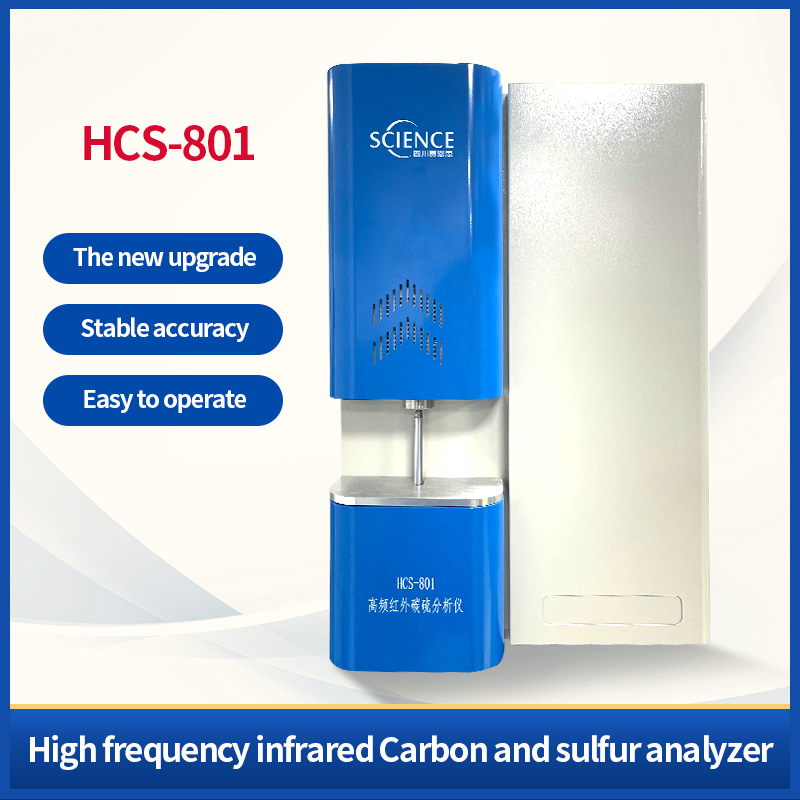

(1)HCS-801 High frequency infrared carbon and sulfur analyzer(2)HCS-800 High frequency infrared carbon and sulfur

2022-04-19

(1) The original model of this type of instrument is HCS-878, which has been produced and sold for 24 years. It is the first generation of carbon and sulfur analyzers with independent intellectual property rights in China. It is designed for steel and alloy materials, with easy operation, stable data, The failure rate is low, providing reliable analysis data for my country's steel production enterprises.

This type of instrument is economical and practical, and it can analyze many metal samples. It is the first choice for small and medium-sized smelting enterprises and Jicheng processing enterprises.

(2) This type of instrument is an upgraded version of HCS-800. After increasing the combustion power, the conversion rate of non-metallic samples has been significantly improved. The new algorithm has made breakthrough progress in the calculation and compensation of ultra-low and ultra-high content data. The key test devices are imported components, which provides data guarantee for large and medium-sized enterprises and multi-variety sample analysis.

This type of instrument is the mainstream type in China. It analyzes metal and non-metal materials. It is the first choice for large and medium-sized enterprises.

High frequency infrared carbon and sulfur analyzer, this product can quickly and accurately determine the mass fraction of carbon and sulfur in steel, iron, alloy, foundry core sand, non-ferrous metals, cement, ores, coke, catalysts and other materials. This set of equipment has introduced advanced technology from abroad. It is a high-tech product integrating optical, mechanical, electrical, computer and analysis technology. It has a wide measurement range, strong anti-interference ability, complete functions, easy operation, accurate and reliable analysis results, etc. Features Polar molecules such as CO2 and SO2 have permanent electric dipole moments, so they have structures such as vibration and rotation. According to quantum mechanics, it can be divided into split energy levels, which can be coupled with the incident infrared light of characteristic wavelength to generate absorption. Gas molecules have a selective absorption spectrum in the infrared light band. When infrared light of a specific wavelength passes through CO2 or SO2 gas, it can generate Strong light absorption.

Since the detector converts optical signals into electrical signals, when the detector works in a linear region, a specific wavelength is selected and the length of the analysis cell (absorption cell) is determined, the measured light intensity can be converted into the amount of ions in the mixed gas. This is the basic principle that infrared absorption method can quantitatively measure gas concentration. The measurement wavelength selected by this instrument: CO2 is 4.26um, SO2 is 7.4um.

The analysis chamber includes a miniature infrared light source, mirrors, modulation motors, absorption cells, filters and detectors. The miniature infrared light source is heated to 800 ℃ by electricity to generate infrared light, which is absorbed by CO2 and SO2 in the absorption cell, and then passes through a narrow-band filter to filter out the energy of other optical radiation other than the above wavelengths, and incident on the detector. The detected light intensity corresponding to the concentration of CO2 and SO2 is converted into an electrical signal by the detector photoelectrically, and then normalized and calibrated by a microcomputer, and the integral inversion becomes the percentage content of carbon and sulfur. A modulation motor is placed between the light source and the absorption cell to modulate the light signal into a 64Hz alternating radiation signal. The center frequency of the detector output is 64Hz.

The electric signal converted by the pyroelectric device is converted into a microcomputer through digital-to-analog conversion after pre-amplification and post-amplification, and is converted into a value proportional to the content of CO2 and SO2 by linearization in the microcomputer.

Sichuan Syense Instrument Co., Ltd. was established in 2016 and is located in Deyang City, Sichuan Province, a major technical equipment manufacturing base in China known as the "Pearl of Western Sichuan". It is a high-tech company integrating R&D, design, production, sales and market services technology companies. Relying on professional technical advantages and rich industry resources, the company has become one of the well-known manufacturers of analytical instruments in the country.

Contact Person:Su Yaqi

Telephone:+8613158695586

Email:susue87619@gmail.com